THE NEWNESS

THE NEWNESS

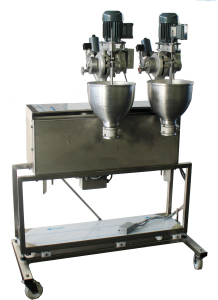

CONTINUOUS DONUT FRYERS SERIE USD2-VSD2

Top-quality of all kind of yeast and non yeast doughnuts due to complete automatic baking process, integrated fat leveling and permanent fat cleaning at a capacity

of 100

to

240

pieces per hour

Ich bin damit einverstanden, dass mir externe Inhalte angezeigt werden. Personenbezogene Daten können an Drittanbieter übermittelt werden. Mehr dazu in unserer Datenschutzerklärung. I consent to external content being displayed to me. Personal data can be transmitted to third parties. Read more about our Data privacy statement.

Proofing

The yeast doughnuts will be proofed on fermentation frames with special proofing and feeding cloth. Roll-in proofer with climate automat and optimal air circulation for one, two or more 18 baking tray trolleys are available. Roll-in proofers are complete double coated for heat insulation.

Feeding

For feeding the fryer the operator puts a baking tray covered with a special cloth and the raised yeast doughnuts on the feeding table of the yeast doughnut feeder (BBA) and removes the tray under the cloth. Then the feeding belt takes over one doughnut row after the other to move them into the fat. For feeding with other types of dough a cake doughnut feeder can be joined to the fryer.

Automatic Baking

The complete automatic baking process includes baking time and temperature control, control of fat level as well as feeding, turning, transportation and unloading of the doughnuts.

Turning

During the baking process the doughnuts will be turned softly up to three times according to the chosen baking program.

Unloading

After the last baking cycle the freshly-baked doughnuts are moved softly over a drain grid and slide out of the fryer.

Doughnut Size Adjustment

By chosing the appropriate baking program the row spacing can be changed for different sizes of doughnuts. The fryer grows with the size of the doughnut. This option is available for fryer type VSD.

Fat Cleaning

A fat filter and cleaning system is also part of the fryer. Permanent fat cleaning extends the life cycle of the fat extraordinarily. It is cost saving and improves the quality of the pastries.

Fat Storage

The entire fat/oil is storaged in the thermally isolated fat container underneath the fryer outside operation hours. The fat/oil retained its temperature at a high level during home time or weekend. Less heat energy is needed and the lifecycle of the fat/oil is extended.

Changeover from one product to another within a few minutes

Fryer Versions

In terms of length, width, row spacing and number of rows the fryer can be adjusted to the needs of a bakery.

Thus, the available space in the bakery can be used at best and the capacity can be optimally matched.

Standard Features

Each system is equipped with a Siemens S7 touch panel control, with three relocatable turning devices, with an integrated fat-leveling system, with a permanent fat cleaning unit, with a fat storage tank, with an electronic temperature controller and with a liftable frying kettle insert frame for easy cleaning and maintenance.

Optional Features

Yeast Doughnut Feeder, Cake Doughnut Feeder, automatic marmelade filling machine, glazing machine, diving grid, cooling down conveyor, turnable sugar bowl, extractor hood with fire-extinguishing system, roll-in proofer with climate automat, tray trolley, baking trays, fermentation frames as well as complete double coated fat storage tank for heat insulation.

| TECHNICAL SPECS: | USD2-6 | USD2-8 | USD2-10 | USD2-8L | USD2-10L | VSD2-6 | VSD2-8 | VSD2-10 |

| Yeast Doughnuts per hour* | 900 | 1200 | 1900 | 2800 | 3500 | 900 | 1200 | 1900 |

| Cake Doughnuts per hour* | 960 | 1280 | 2000 | 2880 | 3600 | 960 | 1280 | 2000 |

| Cake Balls per hour* | 3000 | 4200 | 6480 | 9800 | 12600 | 3000 | 4200 | 6120 |

| max. pastry size (mm) | 110 | 110 | 110 | 110 | 110 | 190/110 | 190/110 | 190/110 |

| Pieces per row | 6 | 8 | 10 | 8 | 10 | 6 | 8 | 10 |

| Number of rows | 15/16 | 15/16 | 19/20 | 35/36 | 35/36 | 8/17 | 8/17 | 9/19 |

| Fat capacity (Ltr.) | 185 | 230 | 338 | 502 | 602 | 195 | 240 | 360 |

| max. length (mm) | 5300 | 5500 | 7200 | 12000 | 12000 | 5700 | 5900 | 7200 |

| Total input (kW) | 37 | 41 | 54 | 82 | 90 | 37 | 41 | 54 |

| Voltage 230/400 Volt | ||||||||

| * in case of 6 minutes baking time |

Specifications subject to change without notice